Capabilities

Capabilities

Understanding Catalyst Inks and Ionomer Dispersions

Laboratory

Lawrence Berkeley National Laboratory (LBNL)Capability Expert

Adam Weber, Ravi Prasher, Xiong PengClass

BenchmarkingCharacterization

Process and Manufacturing Scale-Up

Node Readiness Category

2: Low-Temperature Electrolysis (LTE)Description

Lawrence Berkeley National Laboratory (LBNL) has extensive experience, tools, and methodologies in colloidal science for characterizing complex catalyst inks and dispersions and linking their properties to their function and formation of catalyst layers, membranes, and ionomer films in membrane electrode assemblies (MEAs). The linkages are mainly accomplished through mathematical modeling of the governing phenomena in inks and dispersions, which are validated through advanced characterization tools. These tools have been honed for fuel cells and are applicable to PEM and AEM water electrolysis applications. This is a fundamental node that is geared towards exploring the controlling forces and properties that enable translation from inks to as-formed structures. These engineered catalyst layers and membranes can then be characterized in electrolysis operational tests. As advanced materials for water splitting devices have unknown and unknowable interactions in ink and dispersion form, compared to state of the art precious metal materials and commercial ionomers, this process is the Achilles heel of many scale up and related efforts. Such knowledge gaps are bridged by LBNL expertise and the underlying science-based approach.

The following tools are available in addition to expert knowledge to guide interpretation of results:

- Rheometer, Dynamic/Electrophoretic Light Scattering, Beam line X-ray techniques, Quartz crystal microbalance dissipation, cryo electron microscopy

- Multiscale models to describe interactions of components within the inks

Electrode fabrication can be done using the following tools:

- Ultrasonic spray coater, Blade casting

Resulting catalyst layers can be characterized with the following tools:

- X-ray fluorescence, conductivity, dynamic vapor sorption, porosity, atomic force microscopy, hydrogen transport properties, scanning electron microscopy, electrolysis testing

- Models to describe the catalyst layer structure on multiscale transport and electrochemical performance

The work in this node is synergistic with nodes related to benchmarking performance and characterization of structures, as well as the manufacturing node dedicated towards exploring different processing methods and subsequent respective ink optimization.

Capability Bounds

This capability is bound only by minimal reproducible amount of materials available for evaluation. These should be discussed with the capability expert in order to determine the scope of work based on the amount of material available. If the Advanced Light Source (ALS) X-ray source is required/desired, access and timing will depend on time available based on approved beam line proposals.

Unique Aspects

This is a fundamental node that looks at multicomponent interaction endemic in inks and dispersions, and using modeling, correlating them to the final materials.

Availability

Available.

Benefit

This capability is central for understanding the fundamental interactions between new ionomers, solvents and catalysts in ink form, required for fabrication of electrodes.

Images

Figure 1. Ink properties affect curing, and both will affect the resulting electrode structure and function.1

Figure 2. Inks contain varied multicomponent interactions that can be modeled to understand emergent phenomena and incipient structure formation.1

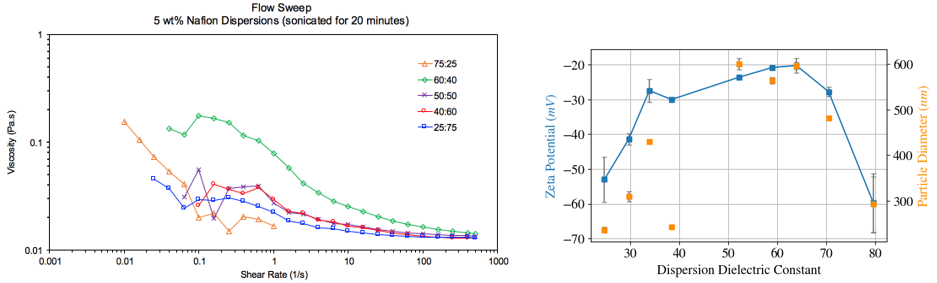

Figure 3. Rheological and solution properties of inks as a function of solvent ratios, resulting particle dimeters. These fundamental properties can be characterized and explored to correlate to desired electrode structure and performance.2

References

1. K. B. Hatzell, M. B. Dixit, S. A. Berlinger, and A. Z. Weber, J. Mater. Chem. A, 5, 20527–20533 (2017).

2. S. A. Berlinger, B. D. McCloskey, and A. Z. Weber, ECS Trans., 80, 309–319 (2017).